Comprehensive Pipeline Welding Inspection: Protecting Infrastructure Integrity

Comprehensive Pipeline Welding Inspection: Protecting Infrastructure Integrity

Blog Article

Advanced Techniques in Pipe Welding Evaluation: Innovations and Technologies for Boosted Accuracy and Reliability in Weld Evaluation

The landscape of pipe welding examination is going through a significant makeover, driven by advanced strategies that guarantee to boost both precision and integrity in weld analyses. Technologies such as automated evaluation systems and progressed imaging technologies are redefining typical methods, while non-destructive testing methods make certain material stability is kept. As these innovations progress, they not only elevate flaw detection prices but additionally make it possible for much more reliable upkeep strategies. However, the effects of these advancements expand beyond prompt advantages, increasing important inquiries concerning future practices and requirements in the sector.

Relevance of Weld Evaluation

Guaranteeing the integrity of pipe welds is crucial to the total security and reliability of commercial systems. Welds offer as the architectural backbone of pipelines, which carry a selection of fluids under differing pressures. Flaws in welding can cause catastrophic failings, leading to not just significant economic losses however also possible ecological calamities and threats to public safety. For that reason, rigorous inspection of welds is indispensable to the lifecycle of pipe infrastructure.

The significance of weld evaluation extends past plain conformity with governing requirements. It works as a positive step to recognize and rectify imperfections, such as insufficient blend, porosity, or fractures, prior to they rise into major concerns. Reliable examination methods also add to the longevity of pipes, reducing maintenance costs and boosting functional efficiency.

In addition, thorough weld examinations foster depend on among stakeholders, consisting of governing bodies, investors, and the areas served by these pipes. By making sure that all welds meet the called for standards, organizations can minimize dangers and promote their credibilities. In summary, weld assessment is vital not only for functional integrity however also for the wider implications it holds for safety and security and environmental stewardship.

Automated Assessment Equipments

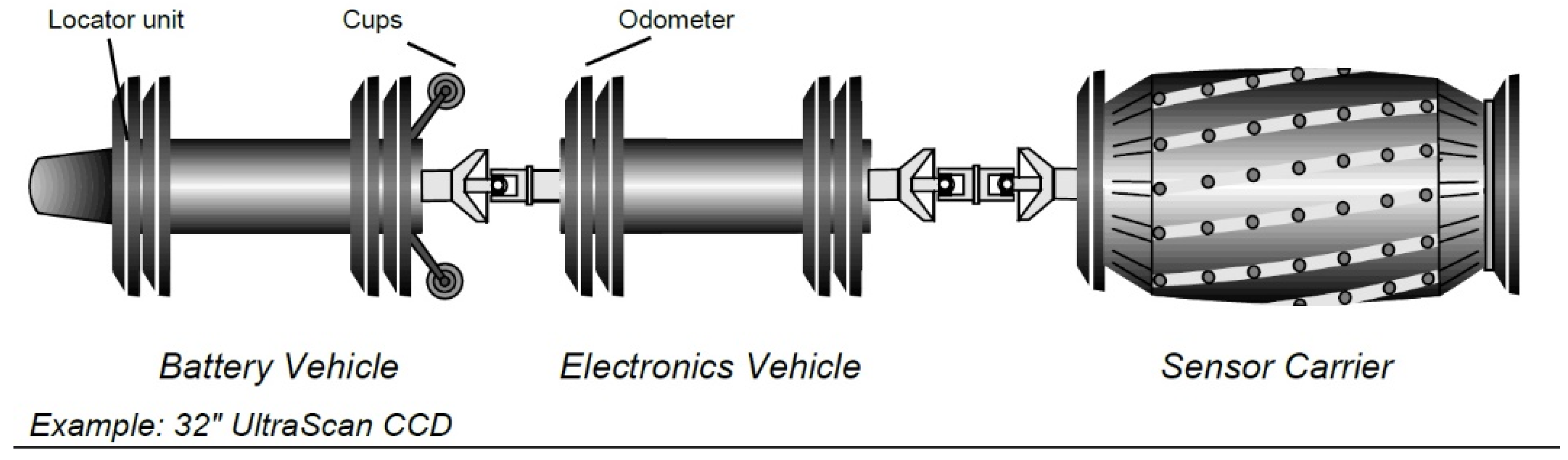

The combination of computerized evaluation systems in pipe welding has revolutionized the strategy to guaranteeing weld quality and honesty. These systems utilize advanced robotics and expert system to carry out examinations that are not only much faster but also much more constant than traditional approaches. Automated systems can cover extensive lengths of pipelines effectively, recording data that human inspectors might ignore as a result of tiredness or ecological problems.

One of the key advantages of automatic inspection systems is their ability to operate in dangerous atmospheres, lowering the threat to human assessors. They make use of numerous non-destructive testing (NDT) techniques, such as ultrasonic testing and magnetic particle assessment, to analyze weld stability without jeopardizing the structure. The data accumulated is processed in real-time, enabling for immediate feedback and prompt corrective activities when flaws are identified.

Additionally, automated systems assist in the standardization of inspection processes, guaranteeing that each weld is assessed against regular criteria. This not just improves the reliability of results but also simplifies conformity with regulative requirements. As industries proceed to focus on security and operational performance, the function of automated inspection systems in pipe welding will undoubtedly expand, leading the way for much more advanced quality control approaches.

Advanced Imaging Technologies

Regularly utilized in modern-day pipeline welding inspections, progressed imaging innovations have actually substantially improved the ability to identify and evaluate weld defects. Strategies such as digital radiography, calculated tomography, and thermographic imaging offer inspectors with high-resolution pictures that disclose sub-surface defects and architectural disparities that may be undetectable to the nude eye.

This leads to much faster assessments and boosted precision in determining crucial flaws. Calculated tomography, on the various other hand, provides three-dimensional imaging, making it possible for assessors to visualize complex geometries and assess the honesty of welds from numerous angles.

Thermographic imaging employs infrared technology to detect variations in temperature level, determining locations of prospective weakness or tension within the weld. These sophisticated imaging technologies not only improve problem detection rates yet additionally reduce the time and sources required for pipeline assessments. Consequently, they play a crucial role in maintaining pipe security and dependability, making sure compliance with industry criteria while minimizing functional threats.

Non-Destructive Examining Techniques

Making use of numerous strategies, non-destructive testing (NDT) methods are essential in pipe welding assessments, permitting for the analysis of weld stability without endangering the material's structural stability. NDT incorporates a series of techniques, including ultrasonic screening (UT), radiographic screening (RT), magnetic bit testing (MT), and color penetrant screening (PT) Each technique has unique advantages and applications relying on the details demands of the evaluation.

Ultrasonic testing makes use of high-frequency acoustic waves to discover internal problems, supplying accurate dimensions of click reference weld thickness and stability. Pipeline Welding Inspection. Radiographic testing employs X-rays or gamma rays to create pictures of the weld, revealing internal problems that may not be noticeable on the surface. Magnetic bit screening works for spotting surface and near-surface gaps in ferromagnetic products, while dye penetrant testing highlights surface area fractures by using a colored color

Incorporating these NDT approaches into pipeline welding examinations boosts the accuracy and dependability of weld assessments, making sure that potential failings are recognized early. As industries demand higher requirements for safety and security and performance, the role of NDT in keeping the integrity of welded frameworks remains to be critical in pipe building and construction and maintenance.

Future Fads in Weld Evaluation

As we want to the future of weld assessment, advancements in modern technology are positioned view to transform the methods employed for examining pipeline honesty. The combination of synthetic intelligence (AI) and maker learning in assessment procedures is anticipated to enhance the accuracy of imperfection discovery and predictive upkeep. These technologies permit for real-time information analysis, making it possible for inspectors to recognize prospective issues prior to they rise into significant troubles.

Additionally, using drones equipped with sophisticated imaging systems is acquiring grip. These airborne evaluations can cover substantial areas promptly, capturing high-resolution pictures and information that can be evaluated for issues in hard-to-reach locations. This not only boosts safety however also enhances effectiveness in the evaluation procedure.

Additionally, the growth of clever sensing units installed in pipe systems supplies the potential for continuous monitoring. These sensors can detect changes in pressure, temperature, and vibrations, offering valuable understandings right into the health and wellness of the welds over time.

Verdict

To conclude, the assimilation of innovative techniques in pipeline welding inspection considerably enhances the accuracy and dependability of weld analyses. Technologies such as automatic evaluation systems, progressed imaging innovations, and non-destructive screening approaches play an important function in improving page defect detection rates and fostering aggressive upkeep techniques. As these modern technologies remain to progress, they will better make certain the safety and security and effectiveness of pipeline systems, inevitably adding to the honesty of important facilities.

Report this page